Restriction orifice plates for effective pressure regulation

To achieve a defined pressure reduction in the processes of your plants or blowout lines, restriction orifice plates are indispensable. A restriction orifice plate is suitable for all single-phase media, for their transport, processing, and forwarding.

Restriction orifice plates, also known as a flow restriction orifice, reduce pressure or limit flows in your facilities during regular operations, but also in case of emergencies. Therefore, they are primarily used in the oil and gas industry, the chemical sector, and power plants. However, restriction orifice plates also prove themselves in general plant construction. In specific cases, restriction orifice plates can also be used for throughput limitation.

At Dosch, we specialize in the design and manufacturing of restriction orifice plates, especially for use in critical applications which involves high-pressure losses, flow velocities, or a risk of cavitation. We provide precise and reliable solutions. Restriction orifice sizing depends on the requirements of the application. Customize restriction orifice plates for your application with us. Rely on our decades of experience.

The advantages of restriction orifice plates at a glance

-

Cost-effective: Restriction orifice plates are more affordable than alternatives, even in applications with higher wear.

-

Customizable: We design our restriction orifice plates specifically according to your requirements and process conditions.

-

Durable: When the correct restriction orifice plate is selected for specific requirements, it is characterized by longevity and reliability.

-

Versatile: Restrictions are suitable for different media, making them a versatile solution in various industries.

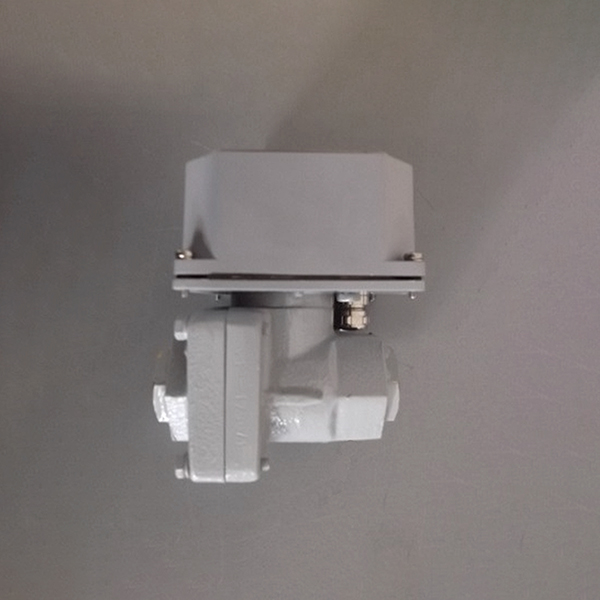

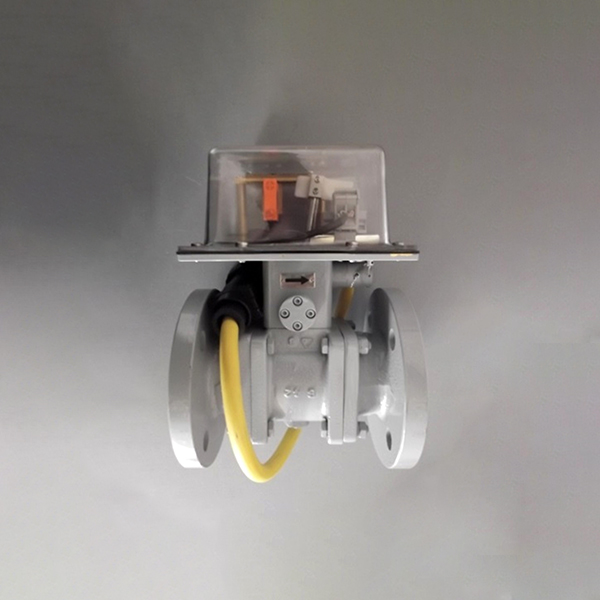

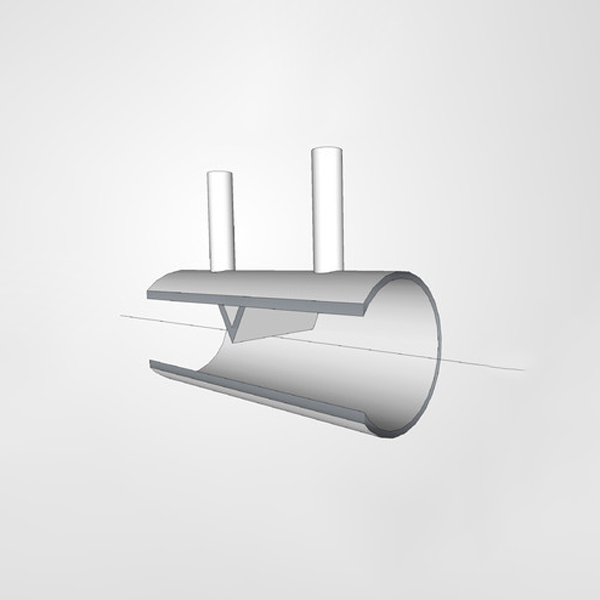

Possible configurations of your flow restriction orifice

Restriction orifice plate design can be different: restriction orifice plates can be delivered as a simple insert disc with an attached handle shield for installation between pipeline flanges with different sealing surfaces, or as a weld-in variant. The bore is generally cylindrical. Stelliting or other hardening of the restriction bore is possible with certain materials to achieve a longer lifespan. For special applications, this can also be eccentrically arranged. multi hole restriction orifice and multi stage restrictions are used when, for example, limits for sound or pressure are required.

Restriction orifice plates for Tengiz, Kazakhstan

Learn how oil and gas extraction facilities successfully use our restriction orifice plates and other products.

Matching accessories

We will be pleased to supply you additionally with the correspondingly required pipe flanges, screws and gaskets.

Do you have any questions? We will be happy to help you.

The main areas of application for restrictor orifices are diverse and cover various branches of industry. Here are a few examples:

- Power generation: Restriction orifice plates play an important role in power generation, especially in power plants, to regulate the pressure and flow of vapours, gases or other media.

- Oil production and refining: Flow restriction orifice are used in the oil and gas industry to control flow rates and pressure in pipelines and refinery processes.

- Water treatment and distribution: They are also used in water treatment and distribution to control water flow and pressure in supply networks.

- Gas processing and transport: Similar to the petroleum industry, restriction orifice plates are used in the gas sector to regulate flow rates and pressures in gas pipelines and plants.

- Chemical and petrochemical: Restriction orifice plates are used in the chemical and petrochemical industries to control process flows, particularly in the handling of chemical reactions and the processing of raw materials.

Not in your industry? No problem, we will develop a custom solution for you.

Restriction orifice plates play a crucial role in reducing and controlling the pressure in pipework systems. They work by constricting the flow cross-section in the pipe, resulting in a pressure drop across the orifice. This pressure reduction is important to keep the flow velocity and pressure of the medium within safe and efficient limits, which is particularly important in process plants and blow-out lines.

Unlike other differential pressure flow elements, restriction orifice plates are customized to suit their individual use cases.

We can customize different restriction orifice plate types and restriction orifice plate sizing especially for you. We therefore need to know the specific purpose of the application in order to prepare a quotation. Then we will find the right solution for your system and manufacture the product.

Restriction orifice plates are available in various designs, including multi hole restriction orifice or as a simple insert disc. For example, as simple plug-in discs with an attached handle plate for installation between pipe flanges and as weld-in variants. The selection of the right orifice plate depends on several factors, such as the specific application, the flow and pressure requirements and the properties of the medium flowing through. Dosch can manufacture customized restriction orifice plates specifically for your particular requirements to ensure optimal results.

The calculation of a restriction orifice plate is an important process in fluid mechanics and dynamics. It enables precise control of the fluid flow in various industrial applications. The restriction orifice plate calculation can be roughly divided into six steps:

- Determine flow conditions : To calculate a restriction orifice plate, you must first identify the fluid parameters such as density, viscosity and temperature. It is also crucial to determine the desired flow rate as well as the inlet and outlet pressures.

- Determine restriction orifice plate coefficient (Cv): The restriction orifice plate coefficient (Cv) is an essential measure of the flow rate through the restriction orifice plate. This value can either be determined experimentally or read from table values.

- Dimensioning the restriction orifice plate: Sizing the restriction orifice plate is a critical step. Use the CV values and specific formulae or diagrams for your restriction orifice plate type to calculate the required diameter or size. Pay particular attention to the thickness of the restriction orifice plate to ensure the desired control and stability.

- Consider pressure losses: It is important to consider the pressure loss across the restriction orifice plate. This can be estimated using the Bernoulli equation or special diagrams for your restriction orifice plate type.

- Check cavitation and restricted flow: Avoiding cavitation is a key aspect. Make sure that the calculated restriction orifice plate does not lead to bubble formation or restricted flow. Adjustments to the orifice size may be necessary to avoid this. Different designs may also be helpful to minimize cavitation.

- Documentation and verification: Document all calculations and assumptions. Check the calculated restriction orifice plate for plausibility and consistency with the application requirements.

It is important to consider specific equations and diagrams for the type of restriction orifice plate you are using, as different restriction orifice plates require different calculation methods. For complex applications, it is advisable to consult relevant standards and seek the assistance of engineers or specialists. We will be happy to support you!

Similar products

- Alle

- Accessories

- Differential pressure devices

- Flow switches

- Pressure, temperature, and humidity measurement

- Product highlight

Let us advise you individually!

Dosch Messapparate GmbH

Kamenz Dam 85

12249 Berlin

+49 30 7201530

vertrieb@dosch-gmbh.de